Two primary forms of calcium carbonate used industrially are Precipitated Calcium Carbonate (PCC) and Ground Calcium Carbonate (GCC). Each type possesses unique properties that make it suitable for specific applications.

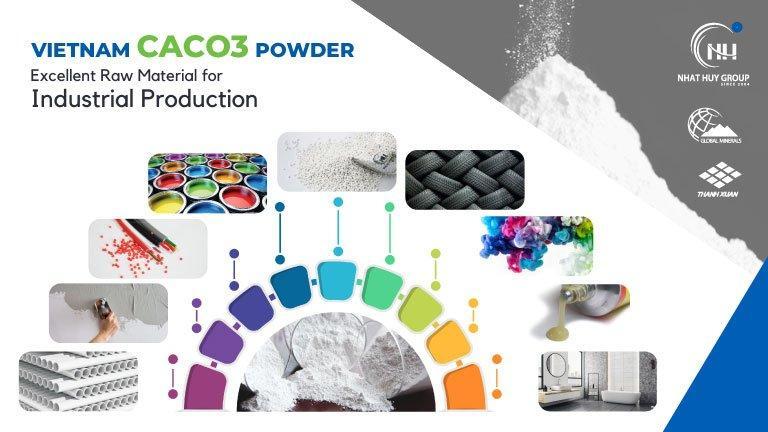

In the diverse world of industrial minerals, calcium carbonate stands out due to its versatile applications in various industries ranging from plastics and paints to food and pharmaceuticals.

Two primary forms of calcium carbonate used industrially are Precipitated Calcium Carbonate (PCC) and Ground Calcium Carbonate (GCC). Each type possesses unique properties that make it suitable for specific applications. At Global Minerals, we specialize in GCC, known for its purity and reliability and backed by over 20 years of industry expertise.

Precipitated Calcium Carbonate (PCC) vs. Ground Calcium Carbonate (GCC)

Precipitated Calcium Carbonate (PCC)

It is manufactured through a chemical process, allowing precise control over the product’s crystal shape, size, and purity.

Typically, it has a higher purity due to the controlled conditions of its production.

The customizable nature of PCC makes it ideal for applications where specific particle morphologies are required for optimal performance.

Ground Calcium Carbonate (GCC)

It is produced by physically grinding and classifying limestone with naturally occurring calcium carbonate.

It contains other natural minerals which can influence its properties in various applications.

It is preferred for its natural origin and broader particle size distribution, which can be beneficial in numerous industrial applications.

Precipitated Calcium Carbonate (PCC) vs. Ground Calcium Carbonate (GCC): Cost Considerations

Precipitated Calcium Carbonate (PCC)

Manufacturing Cost: PCC is typically more expensive to produce than GCC. The chemical synthesis process used to create PCC allows precise particle size and shape control, which can be tailored to specific applications. However, this process involves higher production costs due to its complexity and energy requirements.

Market Price: Due to its customizable properties and higher purity, PCC generally commands a higher market price. This makes PCC a less cost-effective option for applications where the specific characteristics of PCC are optional.

Ground Calcium Carbonate (GCC)

Manufacturing Cost: GCC is produced by physically grinding natural limestone, which makes the process significantly less expensive than the chemical synthesis required for PCC. The simplicity and efficiency of the grinding process keep production costs lower.

Market Price: GCC is typically less expensive than PCC due to lower production costs. This cost-effectiveness makes GCC a favored choice in industries where high purity and specific particle morphology are less critical.

Why Choose Ground Calcium Carbonate (GCC) from Global Minerals?

Trusted Experience

With over 20 years of experience in the industry, Global Minerals has established itself as a leading exporter and manufacturer of high-quality GCC. Our deep understanding of the market needs and technological capabilities ensures that we provide only the best to our clients.

Consistent Quality

Our GCC is renowned for its consistent quality. We source our limestone from the finest deposits and use advanced grinding technology to maintain high purity and particle size distribution standards. This consistency is critical for customers who rely on our GCC for their product formulations.

Versatile Particle Sizes

We offer various micron sizes to cater to different industrial needs. Whether you need fine powders for plastics and paints or coarser grains for building materials, our GCC can be tailored to meet your specific requirements.

Stable Production Capacity

Global Minerals operates several facilities with a substantial production capacity, ensuring a reliable supply of GCC throughout the year. Thanks to our streamlined production processes and robust logistics, our clients can depend on us to meet their demands, even on short notice.

Contact Us

Choosing the correct type of calcium carbonate for your applications is crucial. While PCC offers particle shape and size customization, GCC from Global Minerals offers unparalleled natural quality, consistency, and reliability—attributes that make it the preferred choice for various industrial applications. Backed by decades of expertise and a commitment to excellence, our GCC is here to enhance your products and processes.

Discover more about our Ground Calcium Carbonate (GCC)

Exploring the Benefits of CaCO3 Powder in Filler Masterbatch Applications

Top reasons Vietnam’s CaCO3 Powder is exported to many Asian countries

Elevate Your Product Quality with Premium Coated Calcium Carbonate Powder from Global Minerals

Uncoated Calcium Carbonate Powder: Enhance Your Product Line

| Nhat Huy Group was established in 2004 as an exporter of calcium carbonate powder. Since then, it has developed as a Vietnamese manufacturer with excellent results in international markets. It focuses on calcium carbonate powder, plastic support materials, and quartz slabs. Nhat Huy has exported plastic and building stone materials to foreign countries, and the world is developing. |